ZZombieReloading.comAmmunition Reloading made easy.

3d printed designs for

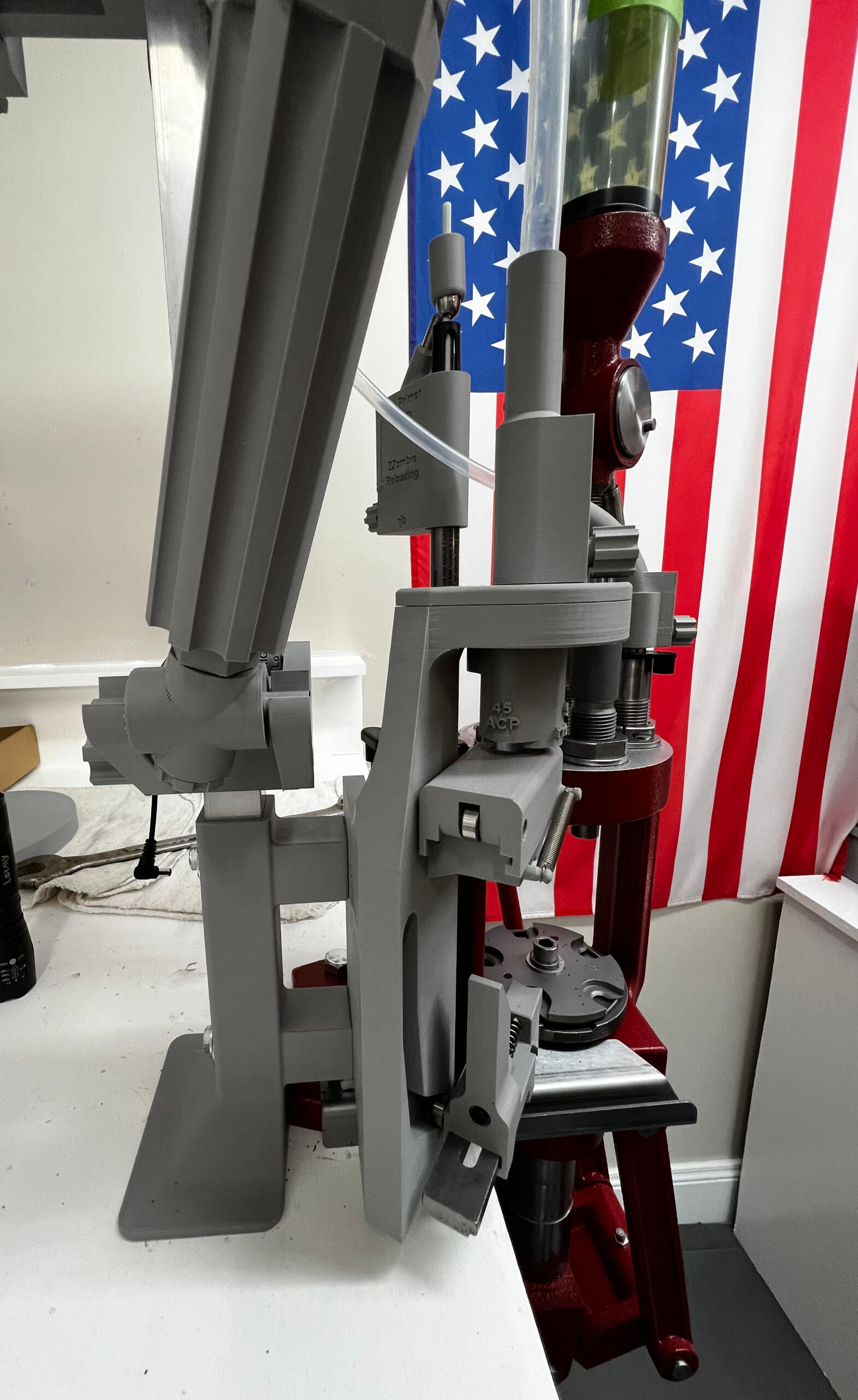

Hornady Lock-N-Load Ammunition Reloading Press

as well as other reloading & gun related products.

Check out our flagship design of the case and bullet drop system.

Project 00.

Videos and Pictures of the Projects below.

...............................................................................

...............................................................................

...............................................................................

Our Designs

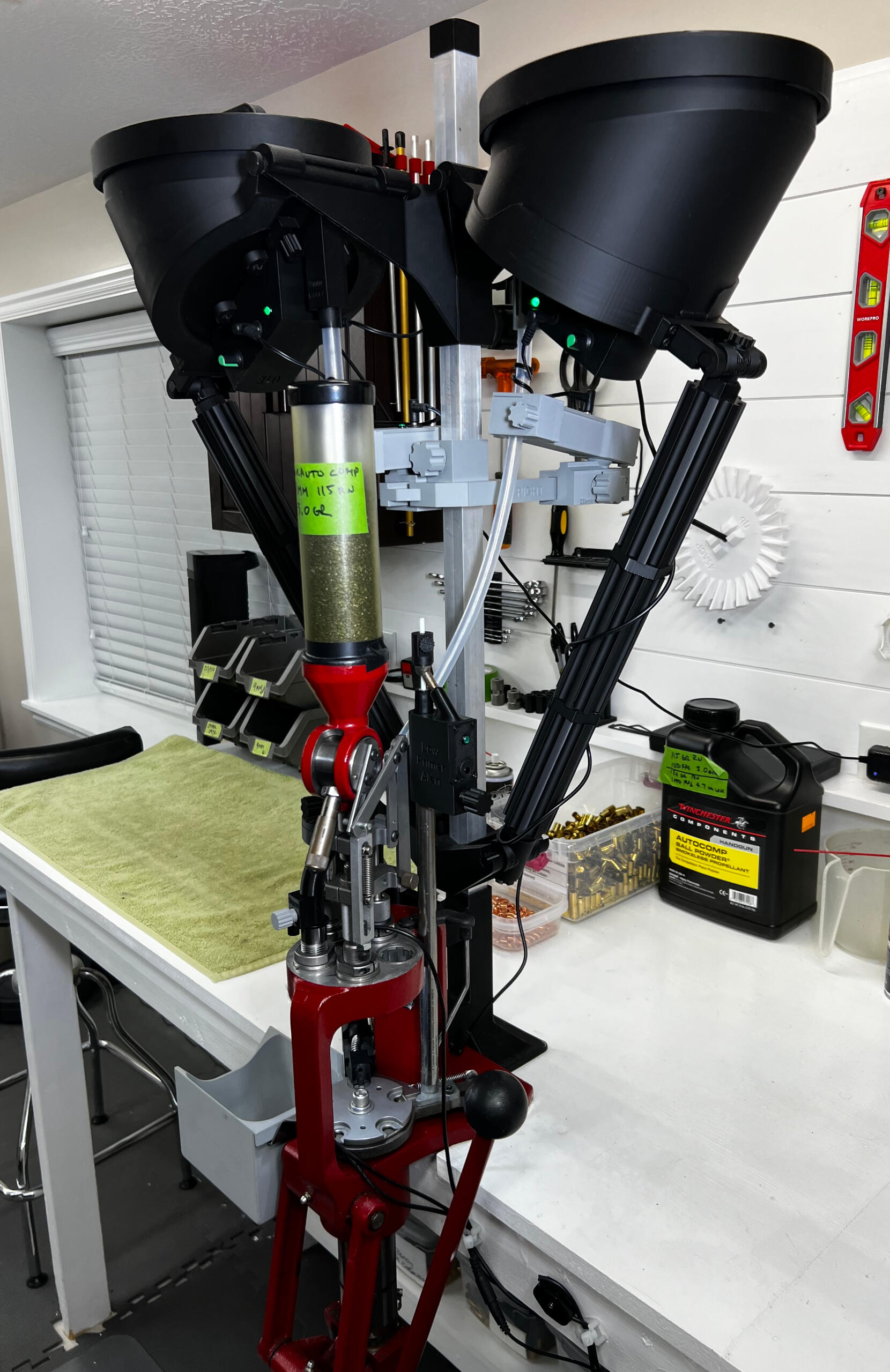

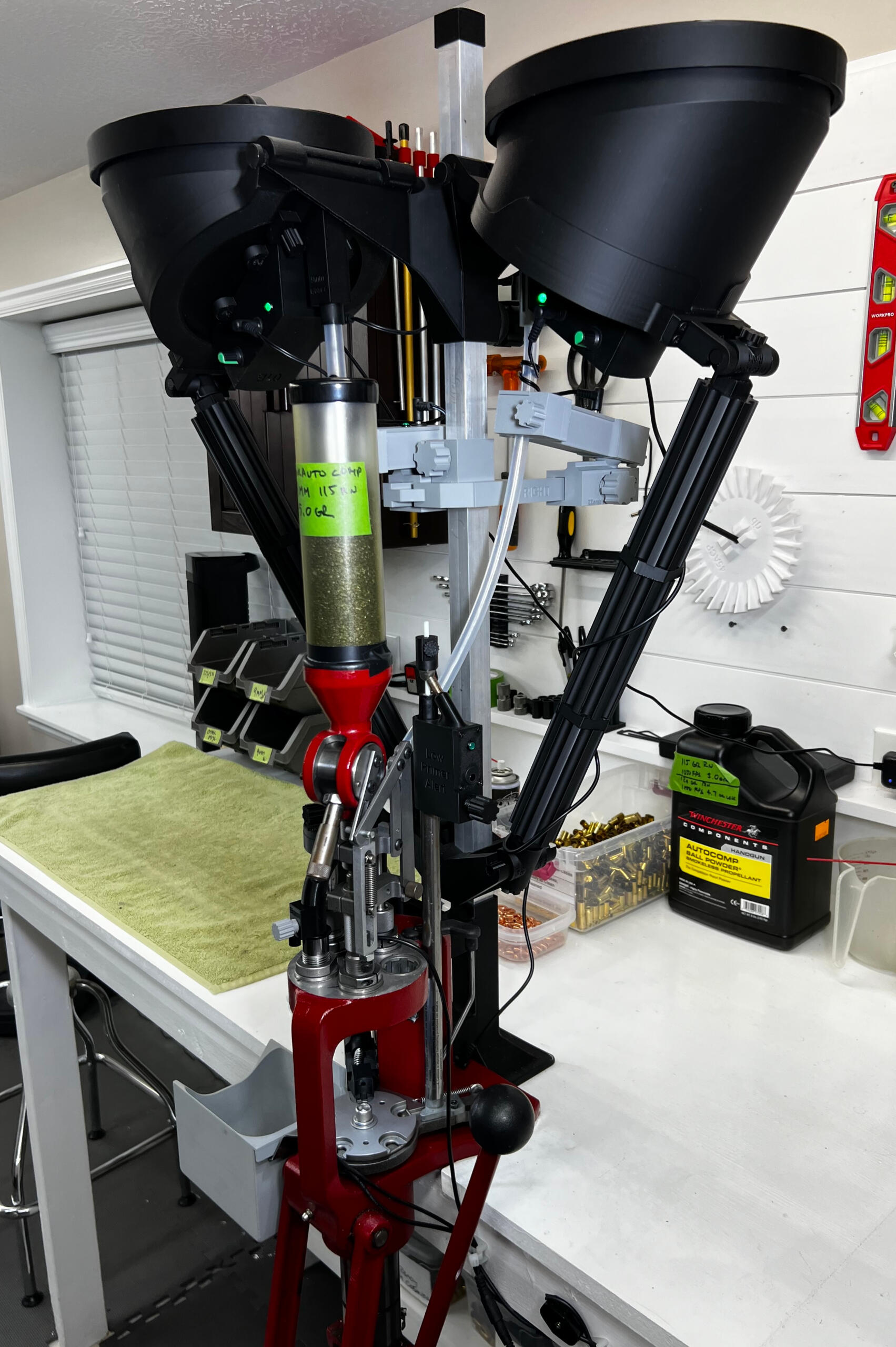

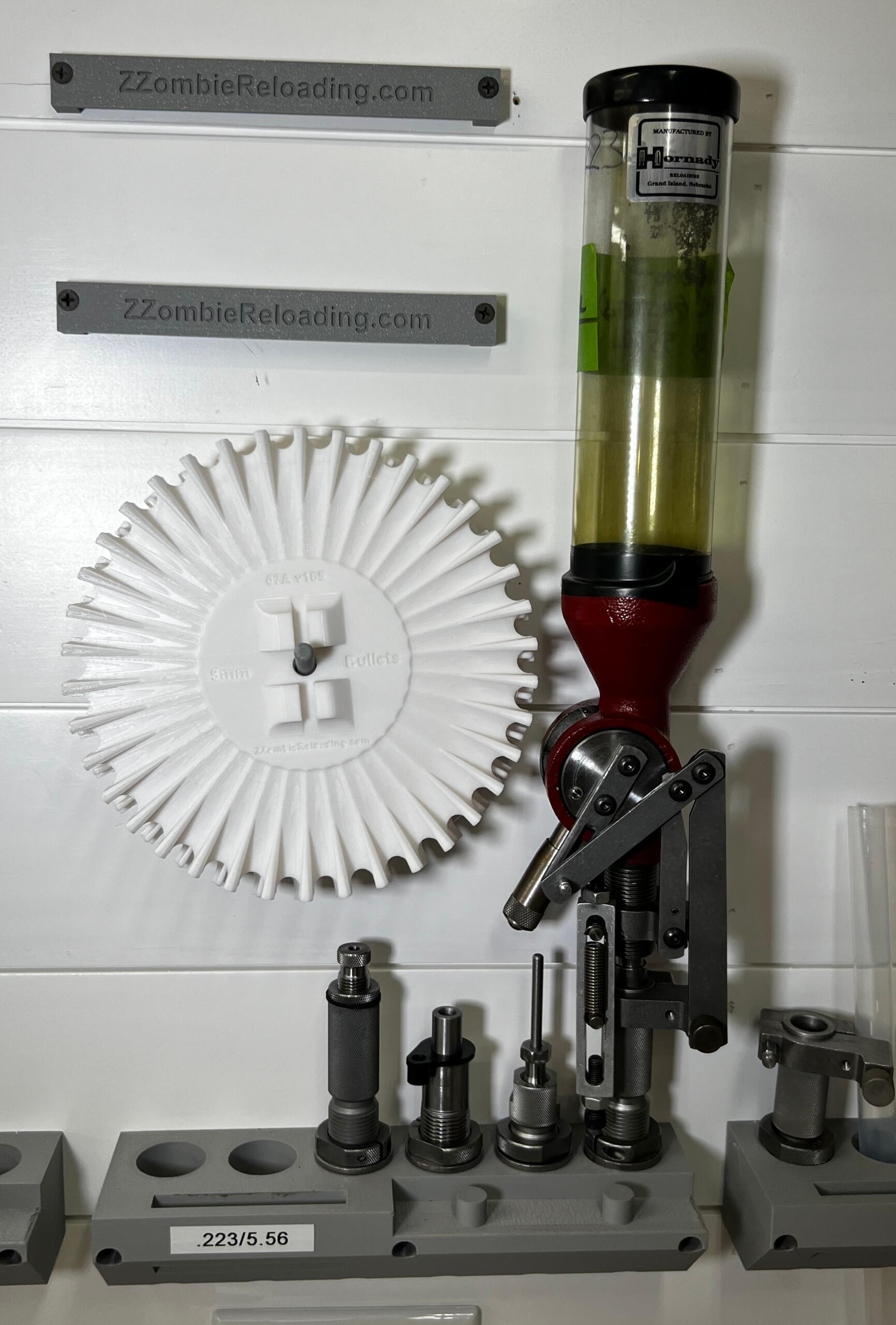

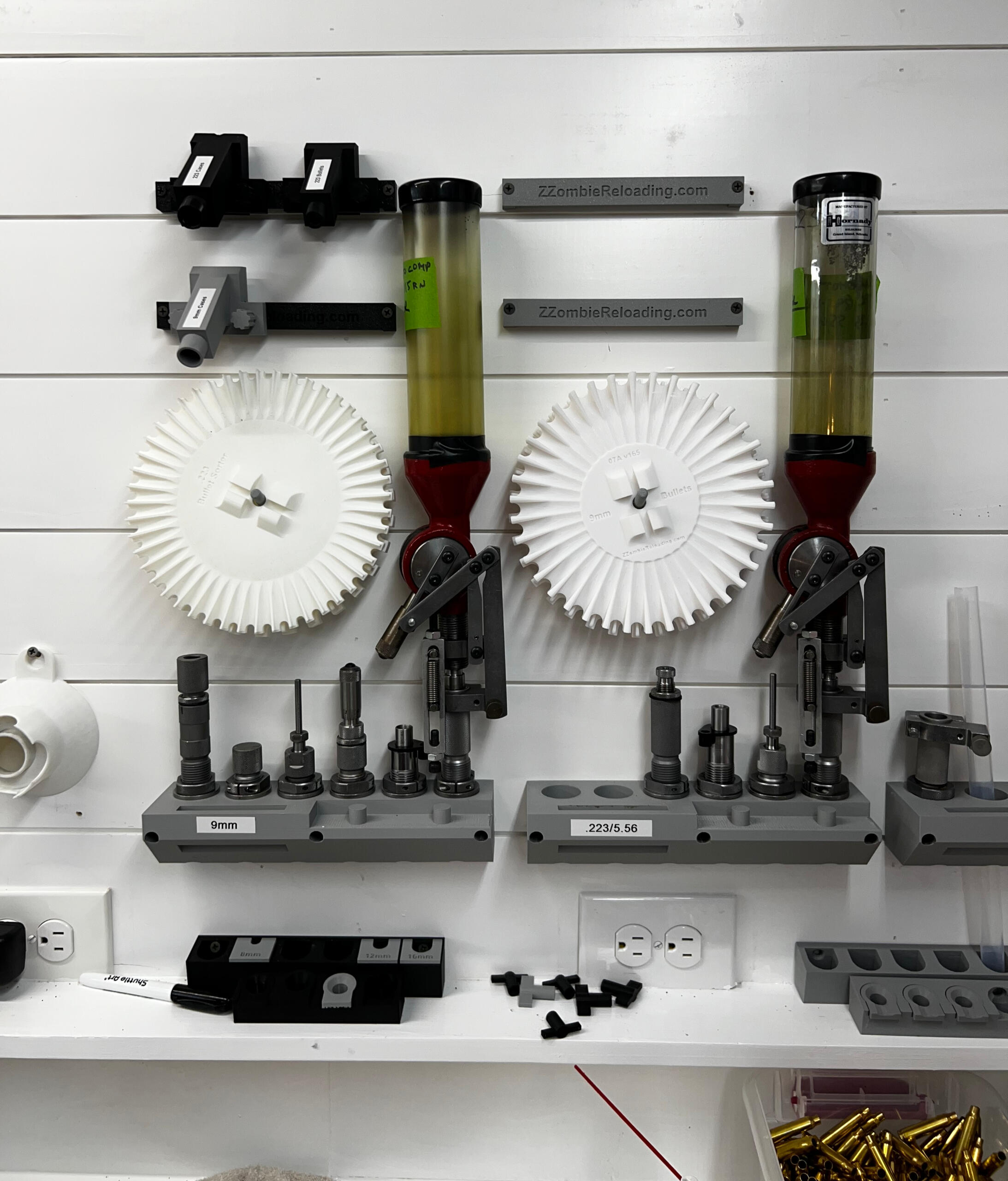

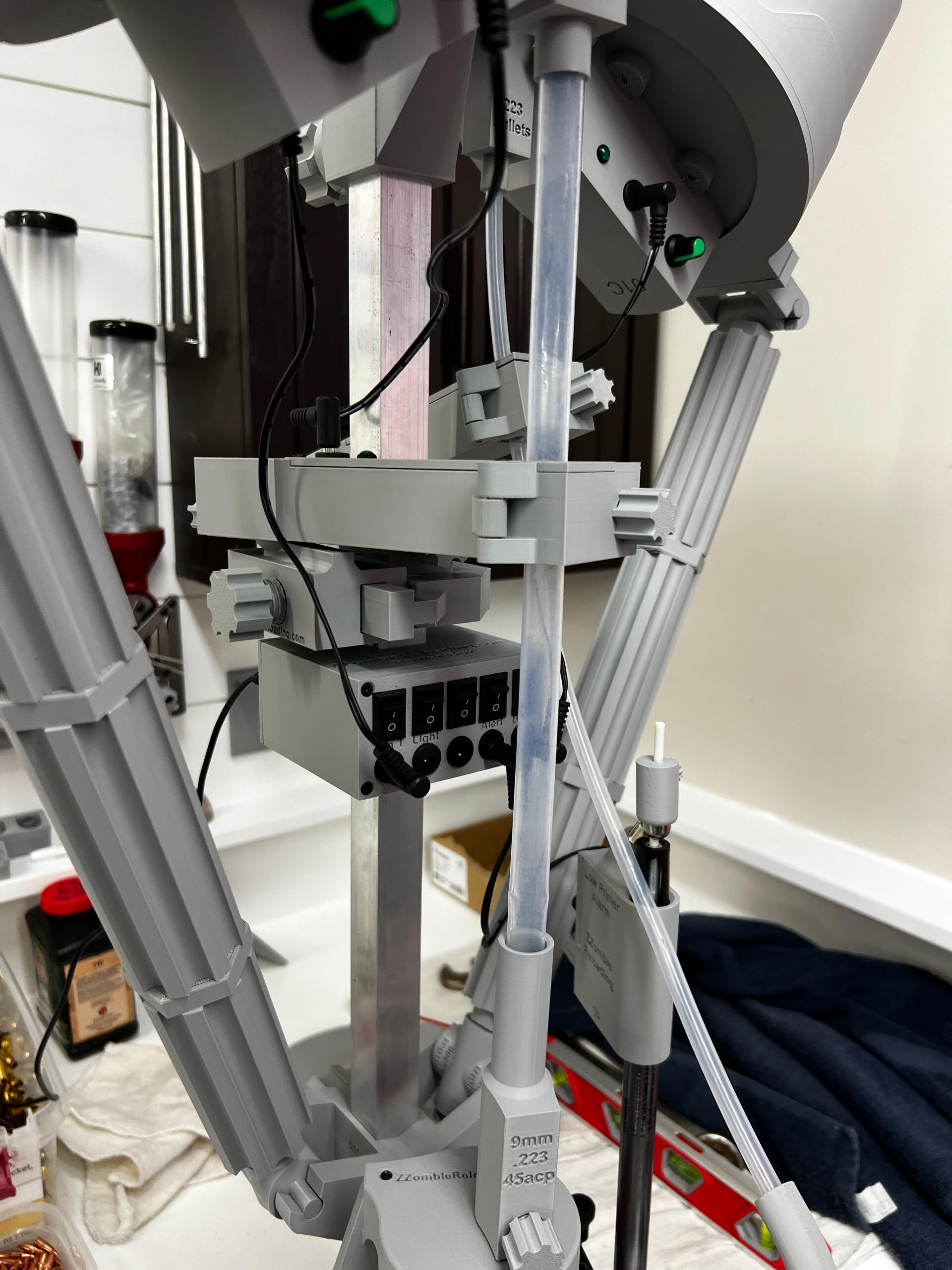

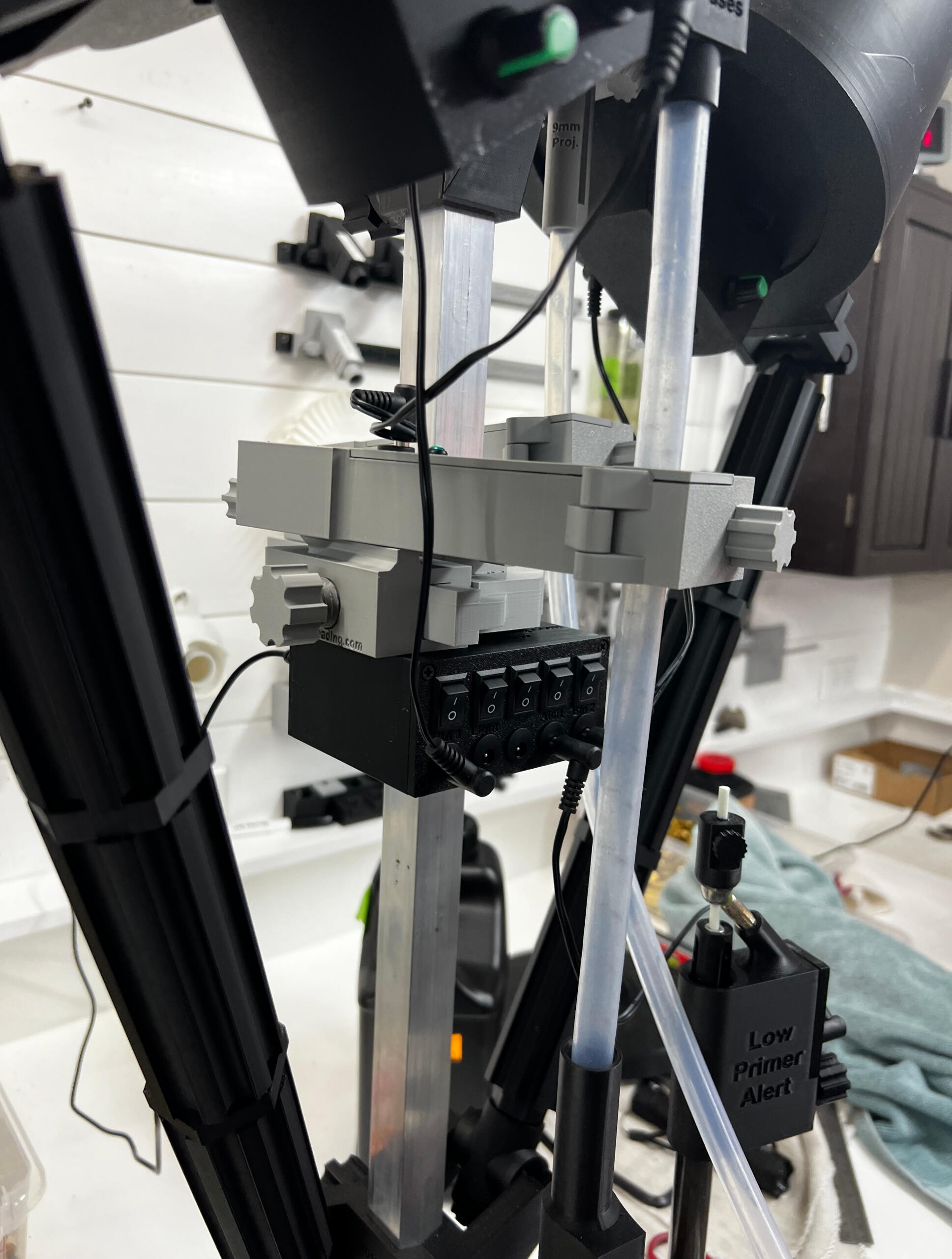

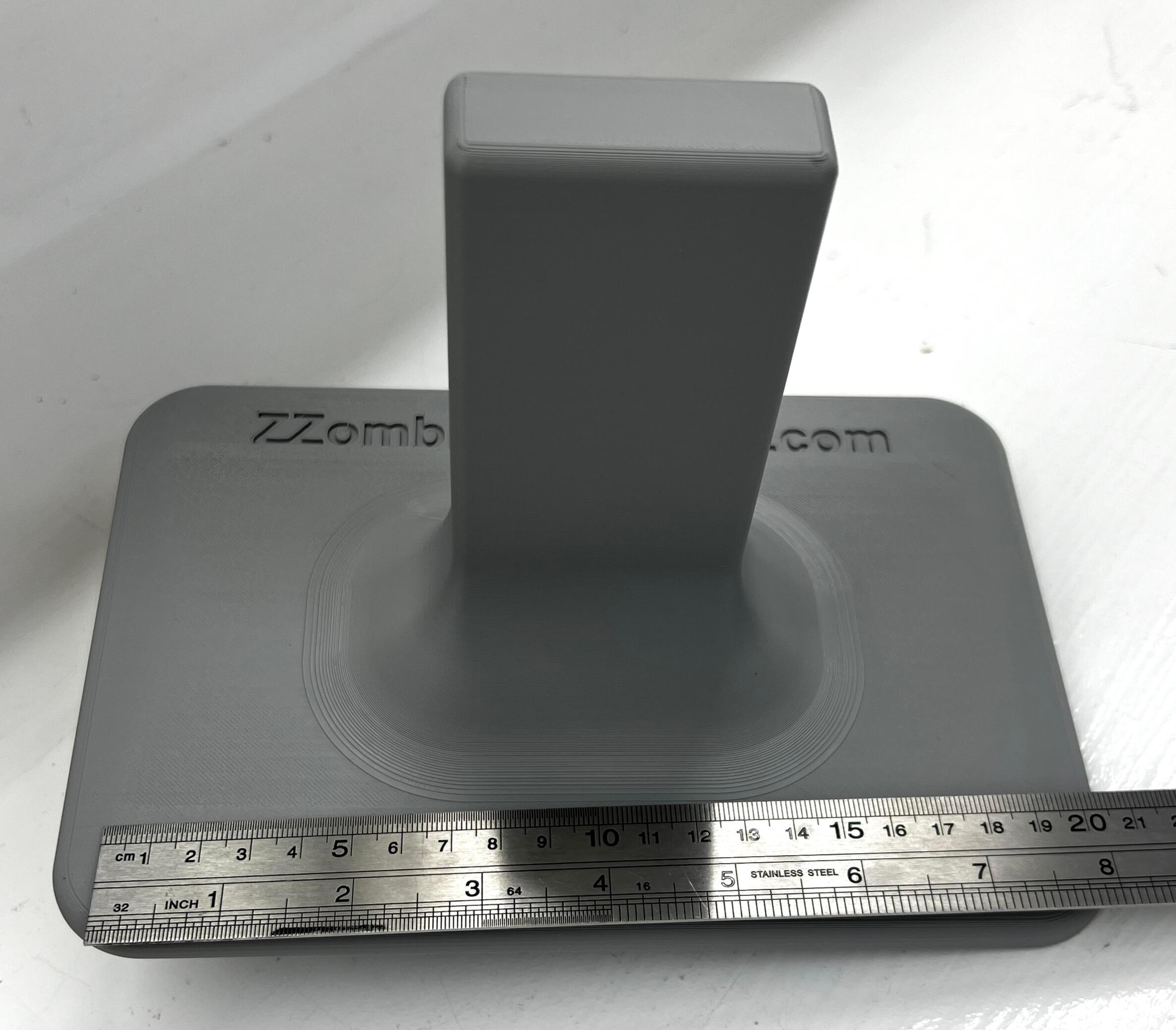

The Flagship design is our Case and Bullet Drop system for the Hornady Lock-N-Load press.....The left Bin is a Case Sorting Bin with sorting plates for 9mm, 45ACP, 223, 6.5 Grendel, 6.5 Creedmore, & .308 Win. (Sorting plates for other case types will be designed and added as needed).....The right Bin is a Sorting Bin with sorting plates for 9mm and 223 projectiles. (Sorting plates for other projectiles will be designed and added as needed).....Motors (speed adjustable) that drive both bins.....Sensors that will stop the motors when the tube fills to a certain level.....Tube that allow visual inspection of the cases and bullets as they drop and are stored in the tubes.....Bullet Delivery System. Designed to be used with the Lee Precision Inline Bullet Dropper Dies. (9mm and 223) (not included)....*Power Box with switches to run everything on the assembly.Other related designs:*Low Primer Alert is designed to be used on the Hornady Lock-N-Load Press.*Case Tumbler (to drop SS pins and trash.) (designed to work manually or with the Franklin Armory Platinum Series Rotary Tumbler)*Spent Primer Holder (for the Hornady spent primer bottle)*Clay Target Holder (for the shooting range)*Wall Mount for the dies.*.223 Case annealing Delivery system. (place cases in the sorter and align the annealer, turn on both the annealer and the delivery system and adjust the motor speed to deliver cases in the correct time frame).*Dual AR15 Magazine Assembly. (they work with virtually any mag).*Die Wall Mounts.*Reloading Catch Bin*4 Slot Parts Tray*Wrench for Hornady LNL case plate.Future Projects in development.

Contact Us at [email protected]

or fill out the following form:

Please email us if you desire additional information.

Thank You

Have a great day!

About:

Guns and Reloading has been my passion for many years. This started with my grandfather taking me to shoot squirrels, gophers and also to target practice. He had a single stage reloading press (for "High Power") and a shotgun shell press. I have fond memories of the time I spent with him during the times he allowed me to stay (and help him) when he was reloading.I am in possession of his cherished Weatherby .22lr and also his greatly loved 12 gauge Browning.I served for 3 years of active duty service in the United States Army (1973 to 1976).I have also served 2 years in the Army Reserve (Texas) and 2 years in the Army National Guard (Minnesota).My service stations were Massachusetts and overseas service at the 7th Radio Resarch Field Station south of Udorn Thailand (1 year) and in South Korea for 14 months. (Pyongtek, Chun Chon, Tong Du Chon).I began reloading about 16 years ago when I bought my first Hornady Lock-N-Load press.A couple of years ago I discovered 3d printing and resolved to streamline the reloading process. I have spent the last year and a half learning modeling programs and 3d printing.The result of this is that I have created an excellent case and bullet drop system achieving 100% proper case and bullet alignment with this assembly.Other designs are also listed. Send me an email if you would like further information on any of the project designs.Enjoy the pics and videos attached.

This is my design of the Clay Target holder.

Below demonstrates the split on the support ring. This split is flexible enough to place on 1-2 inch pipes, branches etc.

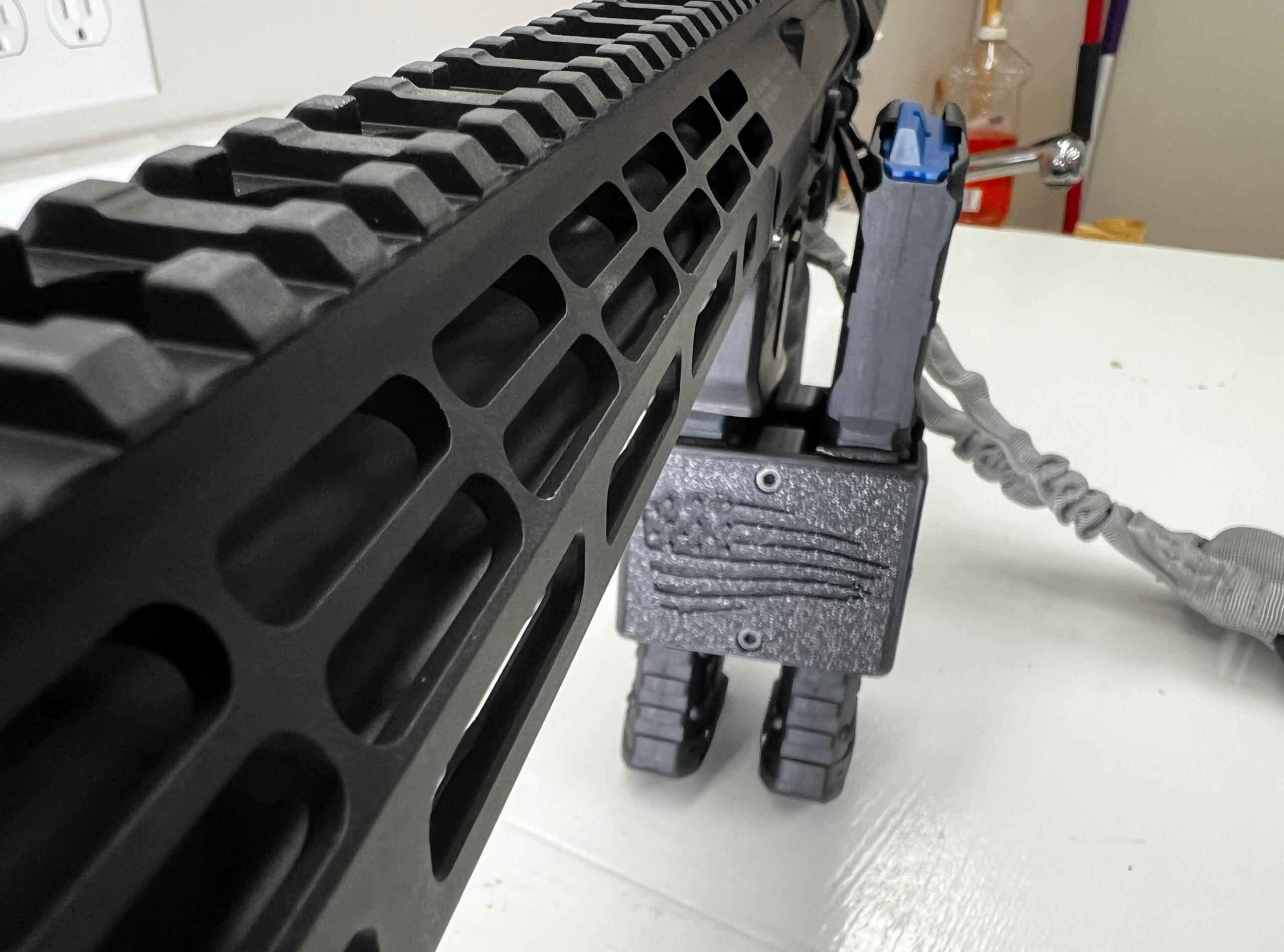

Dual .223/5.56 Magazine Assembly (below)

Cse and Bullet Drop Assembly (in black)

Case Delivery and Bullet Drop System (black)

View from the right of the assembly. The sorting bin is offset to drop cases directly above the Case delivery system ensuring that all types of cases can be accurately delivered.

Below is a video of the operation of the system.

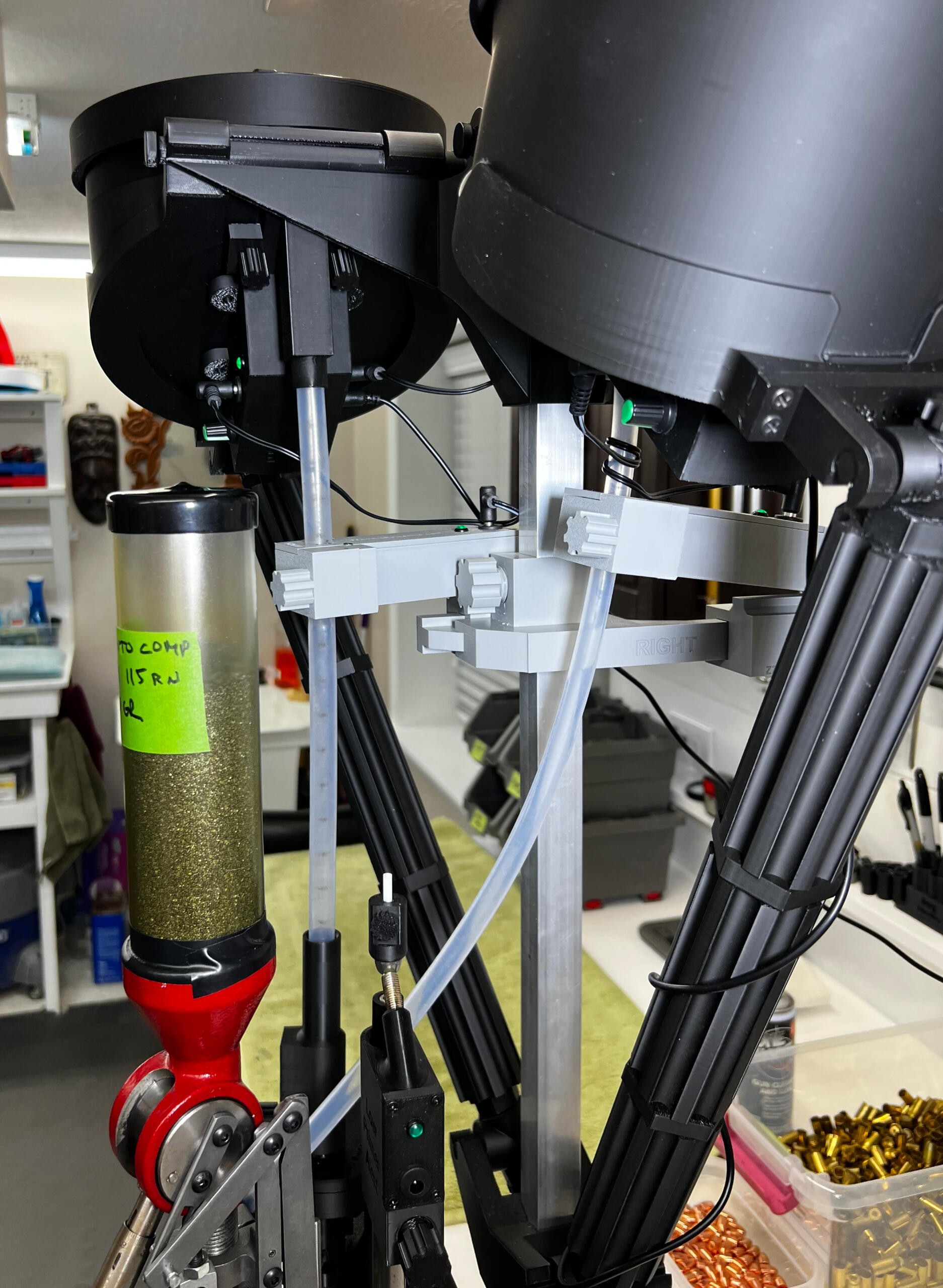

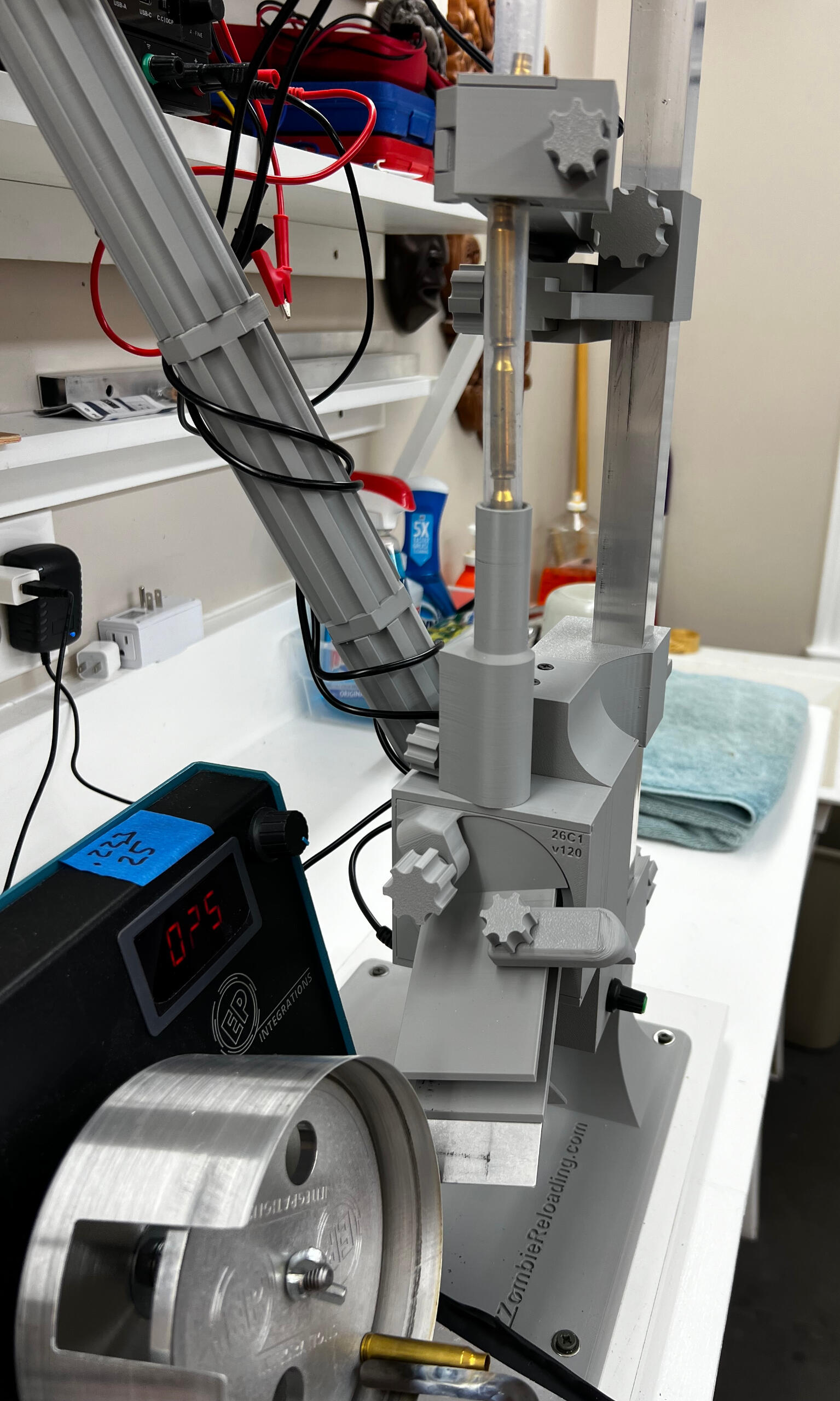

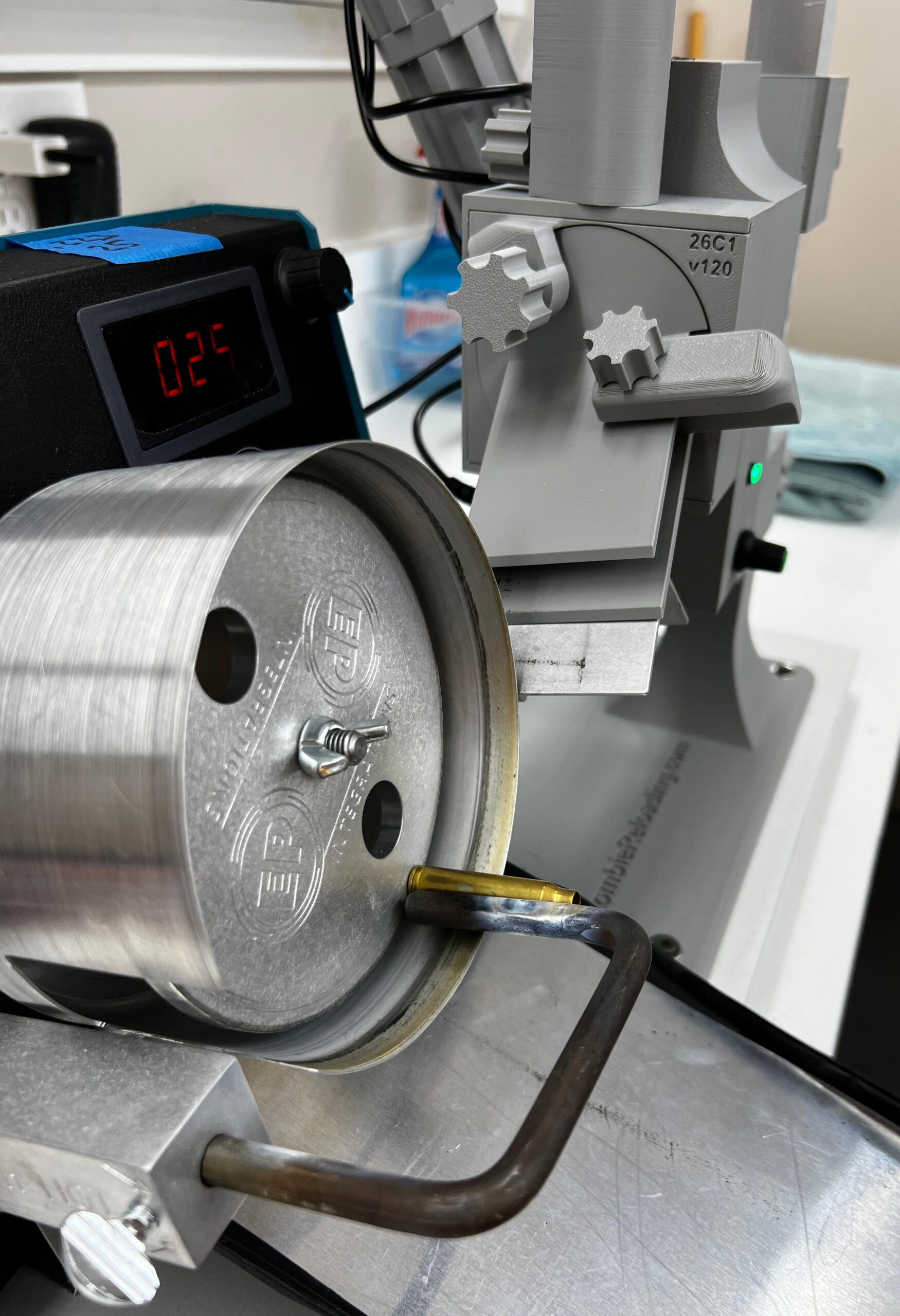

Below is a close up of the sensor assembly.

When the cases reach the sensor, the sorting motor turns off. It turns on again as cases are dropped through the system.

Annealing Assembly

Below-Left View of Casing drop with sensor. When the cases rise to the sensor, the sensor then shuts off the motor to the bin sorter. It activates when the cases drop below the sensor level.

This video shows the assembly in operation.

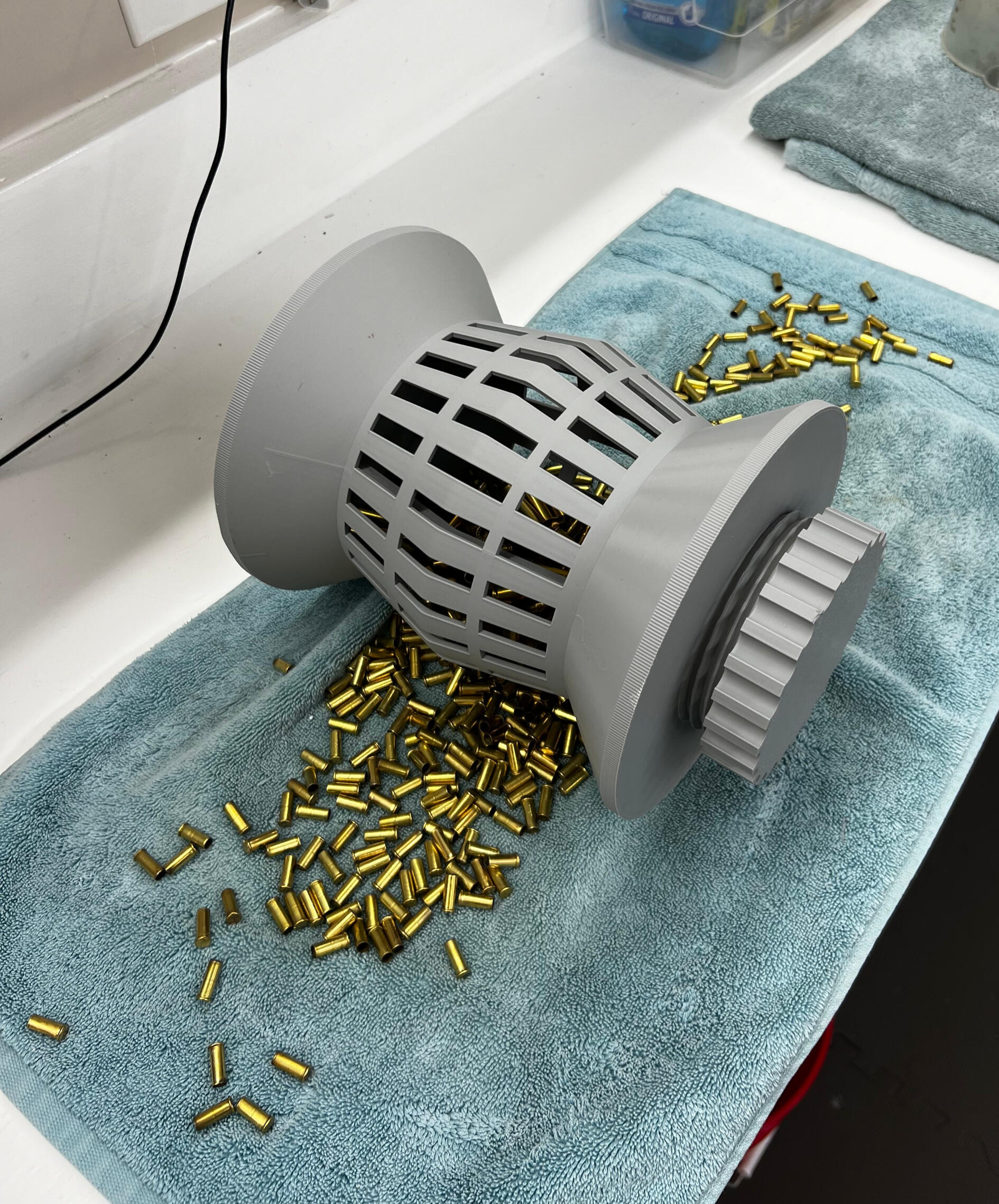

This is the debris removal tumbler. As you can see in the video as well as the pics you can either use this manually or on the Frankford Arsenal Rotary Tumbler motor base.

Below: I added .22lr debris to my mix to demonstrate how it is removed. (see video below).

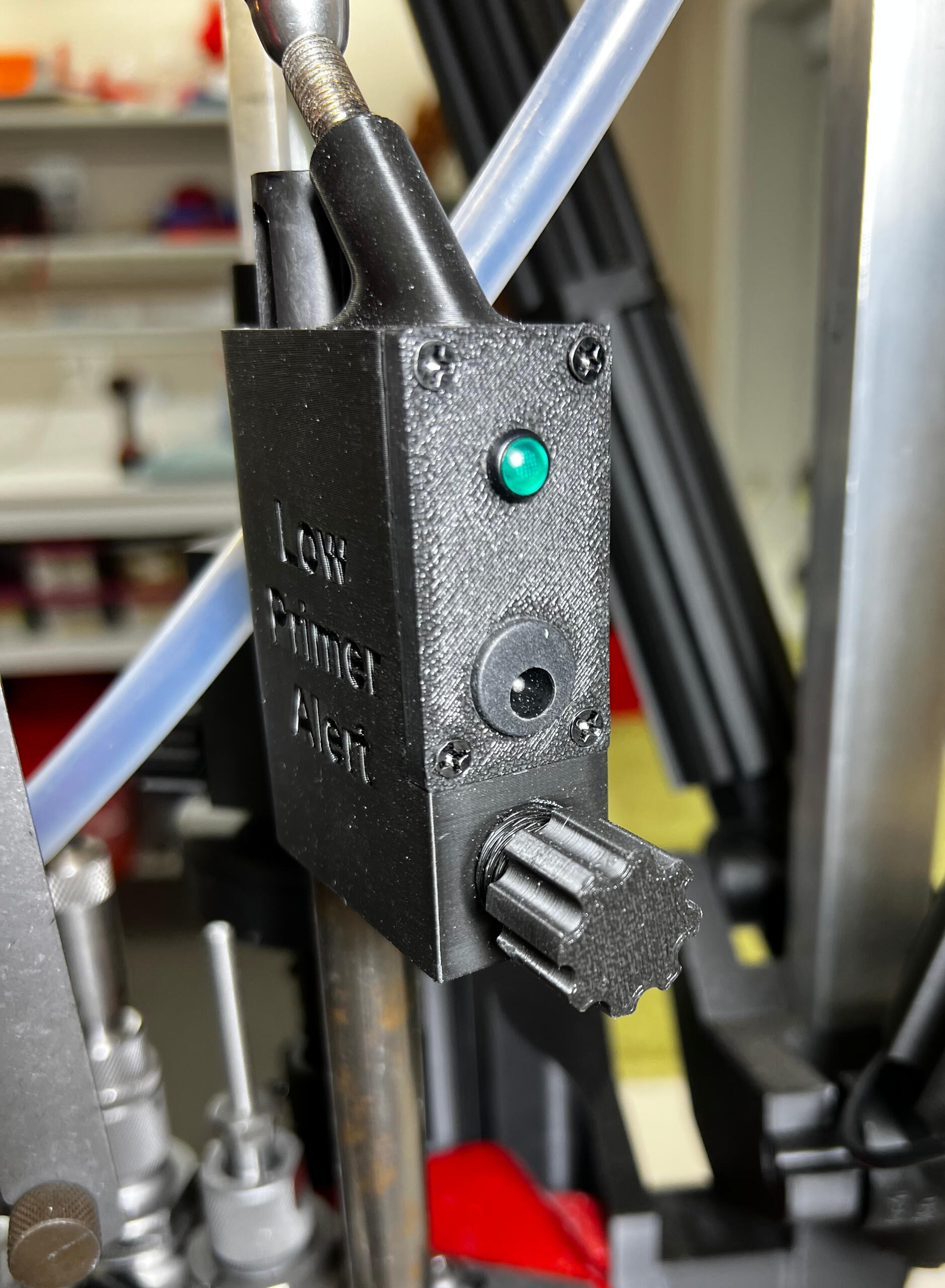

The fiberglass rod has an attachment to set when you want the alert to buzz. As the primers are used the rod and attachment lower. When the metal device touches the sensor on the alert box it will begin buzzing.

This is a useful 4 slot parts tray with inside rounded bottom for easy parts pick-up.

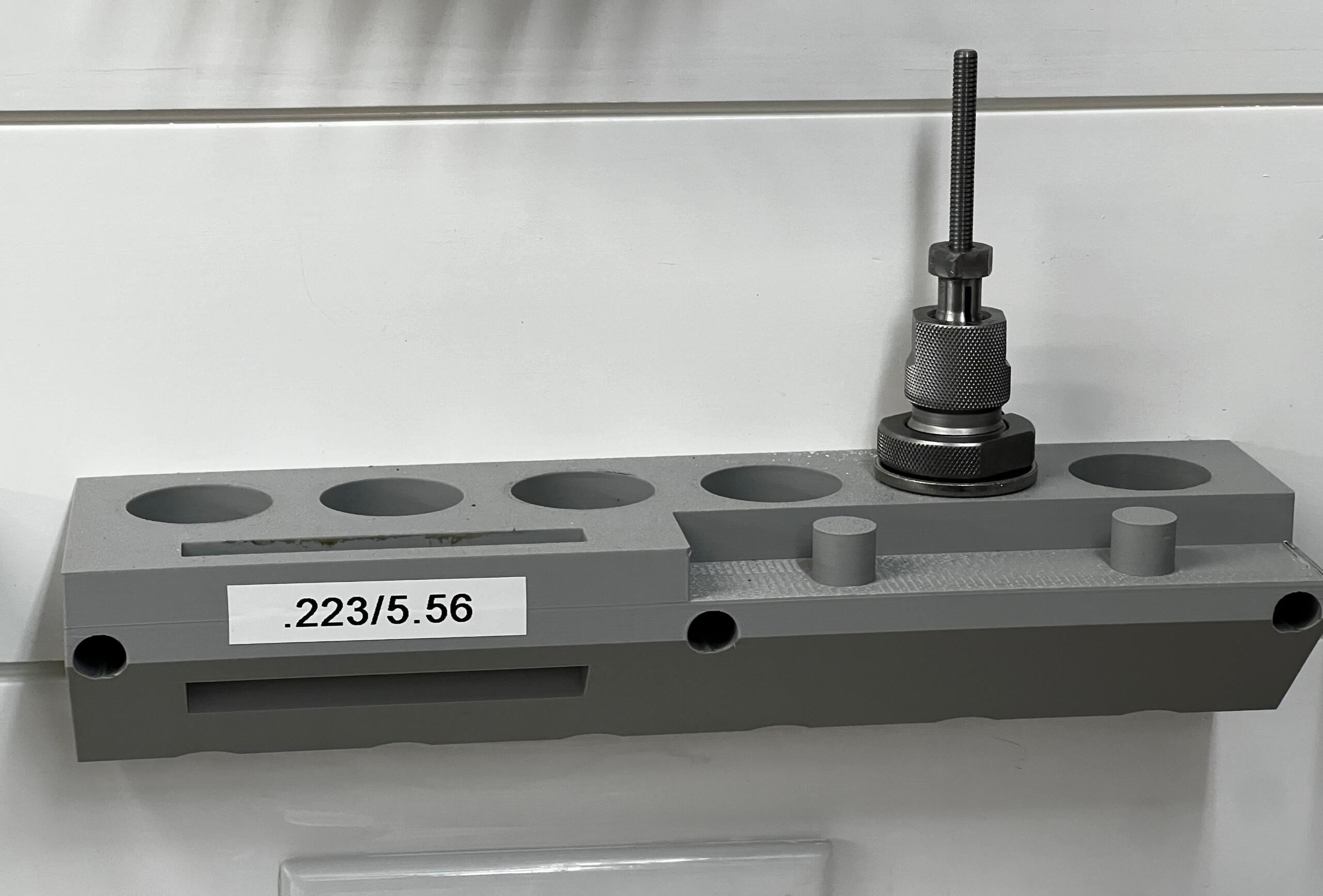

This is a wall mount for all dies.

6 slots for dies, 1 slot for shell plate and 2 mounts for bullet to die drop.

This reloading catch bin is larger than the original. It also has a rounded bottom to easily retrieve completed cartridges.

This is the power box. All power for the bins, primer alert and soon to be press lights can be powered form here. 12 vdc. (only 1 wall power brick is required).

Below is the Power Box printed in black.

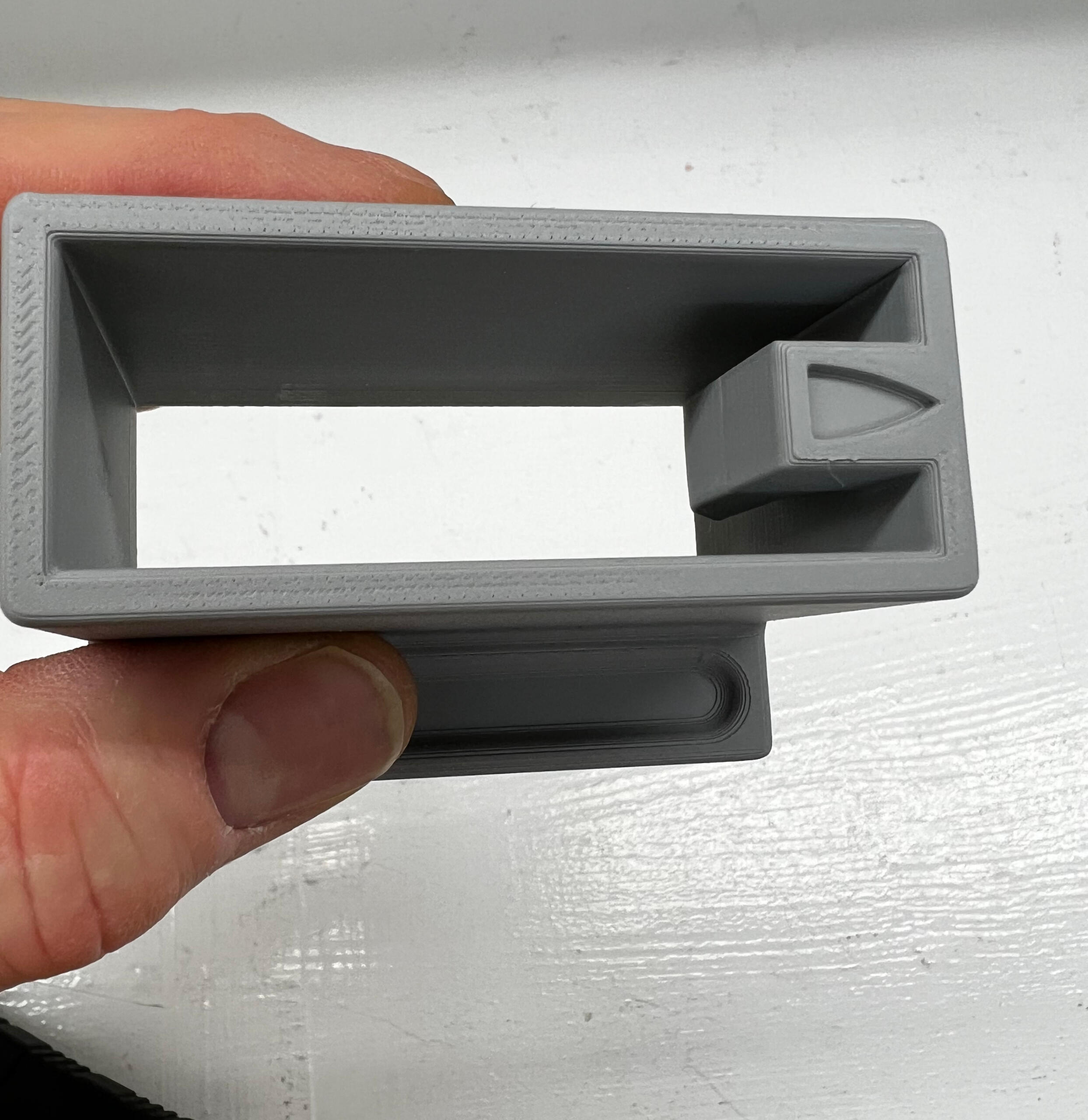

This is the new Case Plate Wrench for the Hornady LNL.

There are two versions as the Hornady LNL Press brace are differenct sizes

(from old version to newer version).

This is project 40, an LED light for Hornady LNL press that plugs into the Power Box. (no additional brick is necessary). One power brick runs the entire system.

Below:

The LED Chips used in this project are the brightest on the market for this size. (LEDs: SMD 2835). 20-30 lumens per chip.

The LED light strip has an adhesive backing for strong adhesion to the press. A wire with plug is attached to the light strip to connect into the power box.

Below:

This is the outcome that we all want. To be able to visually check each case after the powder is dropped into the case.

(shown with a 5.56 case with full powder charge)

This is a remake of the

.22 lr mag loader I have been using for years.Mags it fits:

Volquartsen, Ruger 22/45.

Project 42 is an AR15 Table mag mount.

This can be used for display or working on your rifle.

Below are pics of the Double Stack Pistol Table mount.

Below is the .22 LR

Pistol Table Stand.

Project 48. Speedloader!!

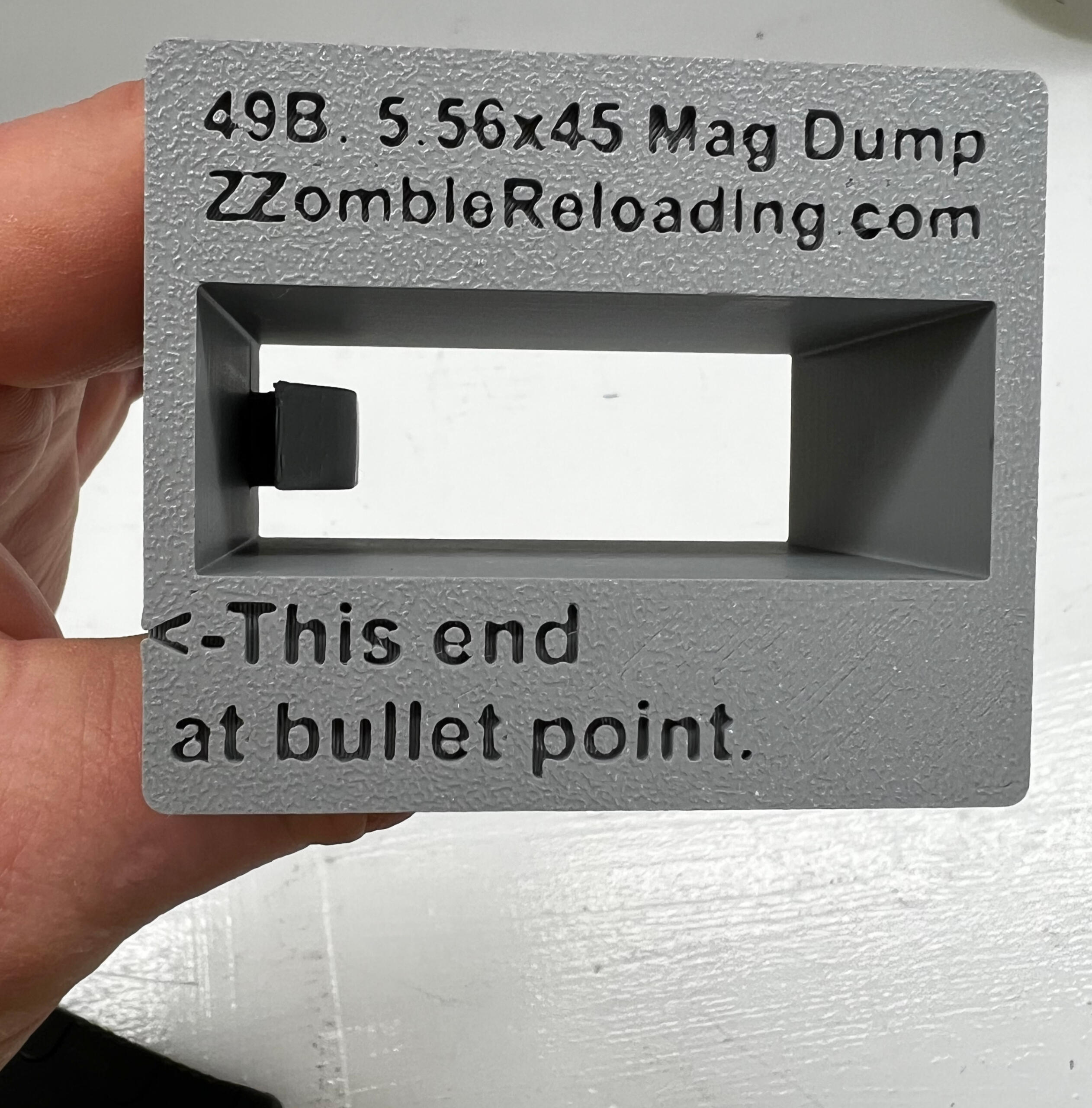

Project 49B: 5.56x45 Magazine Dump

SEO: Hornady, Reloading, 3d, 3d printed, Lee, Lock-n-Load, Bambulab, bambu, .223, 5.56, cases, bullets, reloading tools, 6.5 Creedmore, 6.5 Grendel, .308, Magazine, Case Delivery, Bullet Delivery, CCI Primer, Primer, 9mm reloading, Power box, volquartsen, staccato